The application of thin-walled parts in mechanical manufacturing is becoming more and more widely although their machining remains challenging. Enhancing the CNC machining accuracy of thin-walled parts can improve part quality, increase productivity, reduce costs, and thus promote the development of the advanced equipment manufacturing.

The article analyzes the factors affecting the quality of CNC machining of thin-walled parts, including machining process, external load, temperature coefficient and tooling, etc, and puts forward measures to improve the quality of machining, so as to effectively solve the precision machining problems of thin-walled parts, ensure the accuracy and quality of the product, and then improve the product qualification rate.

Importance of Improving the Machining Accuracy of Thin-Walled Parts

Improving part quality

The accuracy with which thin-walled parts are manufactured can have a significant impact on the use and quality of the parts. CNC machining of thin-walled parts can significantly reduce errors in the manufacturing process, thereby improving their reliability and stability.

Increase productivity and reduce costs

Improve the accuracy of CNC machining of thin-walled parts, can reduce the manufacturing process of waste and rework, and can shorten the manufacturing time, increase productivity, and thus reduce manufacturing costs.

Promote the development of high-end equipment manufacturing

Thin-walled parts are widely used in the product prototype development of aerospace, aviation, and automotive industries. Precision CNC machining of thin-walled parts is a crucial method to achieve their high performance and high quality. This is of great significance for enhancing the manufacturing level of high-end equipment in our country.

Improve international competitiveness

In the context of the accelerated process of global integration, the competition between countries is becoming increasingly fierce. Enhancing the precision of CNC machining of thin-walled parts will lay the foundation for solving the CNC manufacturing problems of complex components, which is of great significance for enhancing the international competitiveness of China’s manufacturing industry.

To this end, it is necessary to increase scientific and technological research and development efforts to promote the continuous innovation of thin-walled parts machining process.

Factors Affecting the Machining Quality of Thin-Walled Parts

Machining process

Unreasonable machining process and chip flow is an important cause of thin-walled parts bending. Finishing is not carried out before the relaxation of deformation and CNC machining when the cutting amount is too large, will lead to deformation of thin-walled parts. In addition, the wrong direction of chip flow can cause the tool and workpiece to clamp each other, thus causing plastic deformation of thin-walled parts.

External load

Thin-walled parts of the material is very thin, in the role of external load will produce a certain deformation, which has a different degree of impact on its shape and length. For example, when using a three-jaw chuck to hold a workpiece, the thin-walled workpiece becomes triangular in shape due to the force applied, resulting in an uneven distribution of the cutting allowance in the bore of the workpiece.

When the collet is released after cutting the bore, the workpiece is returned to its original shape by the elastic force, resulting in an error in the process.

Temperature coefficient

Generally speaking, under the influence of cutting heat, workpieces with small thicknesses are subject to different degrees of thermal deformation during machining, which reduces the manufacturing accuracy and quality of the workpieces. After the thin-walled parts are clamped, finishing, semi-finishing and roughing processes are carried out sequentially. As a result of high temperatures, thin-walled parts are deformed, making it difficult to guarantee the accuracy of the workpiece.

Tooling

In the machining process, the tool will have two effects on thin-walled parts. Firstly, when machining to overcome the elastic deformation of the material phenomenon. Thin-walled parts themselves are prone to plastic deformation, and most of the friction between the tool and the part will be transformed into chip heat, resulting in uneven temperatures within the part, which is prone to deformation.

Second, the cutting force. Cutting force is easy to make the workpiece rebound, if the force is too large, beyond the elastic limit of the material, will cause extrusion deformation. In addition, due to the influence of the cutting force, the machine tool is very prone to oscillation, which in turn reduces the machining accuracy.

How to Improve the Machining Quality of Thin-Walled Parts

In order to improve the manufacturing accuracy, it is necessary to consider the mechanical properties, thermal stability, and machinability of the material, and select the appropriate material. For example, choosing materials with high strength and small expansion coefficients can reduce the deformation during machining.

Heat treatment has a great influence on the precision of thin-walled parts, and precise control of heating temperature, time and cooling speed can eliminate internal stress and improve the stability and precision of parts. The formulation of a strict production process management system can ensure that there are clear operational specifications and quality control standards for all aspects of the process from the entry of raw materials to the exit of finished products.

At the same time, the process parameters should be optimized by combining process experiments and data analysis to improve the stability of the machining process, and reasonably arrange the sequence of each process to avoid deformation of the workpiece due to factors such as temperature and stress.

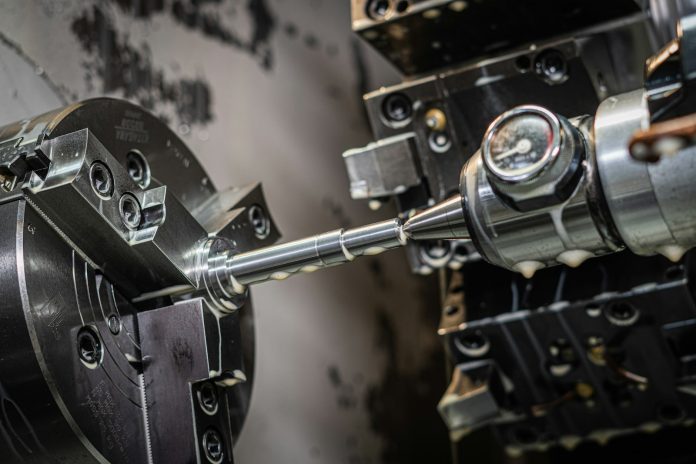

In addition, the use of advanced technology, such as CNC turning and grinding, can effectively complete high-precision cutting and control the surface roughness. The use of high rigidity machine tools can reduce the error caused by vibration and deformation during cutting, so that the machine tool can maintain a good working condition during the use of the machine tool and reduce the number of failures and downtimes.

The use of cutting force sensors, temperature sensors to monitor the cutting process in real time, according to the monitoring results of timely adjustment of the cutting dosage, can ensure that the cutting parameters are in the optimal state, to ensure the stability of cutting.