At a press conference streamed out of South Korea this afternoon, Samsung has confirmed that it was battery manufacturing defects which led to the widely publicised issues befalling the Galaxy Note 7, and its eventual recall. The good news for Samsung is that – for the most part – the hardware of the phone itself was not a factor in the failures.

Samsung conducted a significant internal investigation, and in addition to this, it engaged the services of three independent consultants to look at different aspects of the Note 7’s failure. In particular, safety consulting firms UL and Exponent examined the battery cells themselves, the Note 7 hardware, and the interaction of the two, and TUV Rheinland looked at the logistics and manufacturing capability to determine whether external factors were at play.

What caused the failures?

The root cause of the problems? Defective batteries, but it isn’t as simple as this — as you may recall, the Note 7 was released in effectively two versions; the original Note 7, and the newer ‘Safe’ Note 7’s which turned out to be rather not safe.

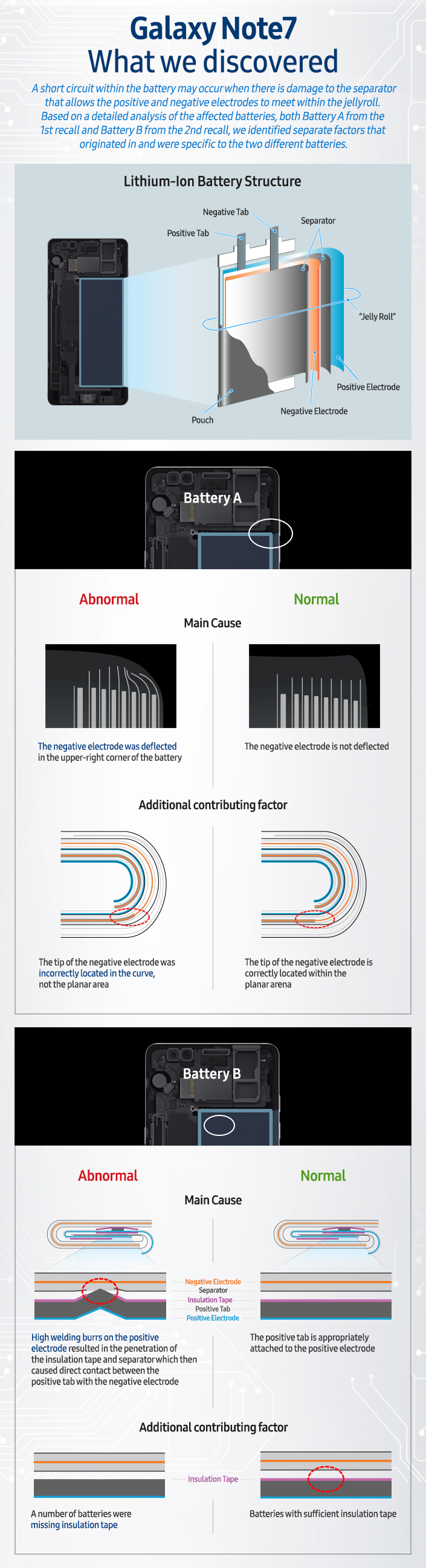

The problem with the first batteries was essentially one of size; Samsung specified a high capacity battery and a relatively small space to fit it into, and the manufacturing of the ‘jelly roll’ internals of the Li-Ion battery, and its enclosure in a soft pouch, led to an infringement on the positive and negative components within the battery, leading to short circuit and failure.

The second, so-called Safe Note 7’s used batteries from a different manufacturer, which faced different issues. It wasn’t the internal construction or the infringement on corners which caused problems, but rather an apparent lack of sufficient quality control which led to failures. In short, welding defects connecting the interface tabs to the negative and positive components within the Li-Ion battery, and missing/ineffective insulating protective tape led to a different kind of failure, which eventually resulted in short circuit, thermal runaway and fire.

Samsung have provided us with this infographic which explains in simple terms what went wrong with each of the two battery designs:

How was it investigated?

Samsung’s investigation was unquestionably thorough. Samsung made a point of showing the processes it followed, including the design and use of a large battery charging facility, designed to replicate user use, charge and discharge processes. Tests included isolating various components of the Note 7 to determine whether any hardware was at fault, including wireless charging circuitry, iris scanner, USB-C port and interface, waterproofing, and whether drops or other factors were at play.

Through all of this, Samsung found the same failure rate regardless of the variables manipulated, leading to the conclusion it was the batteries rather than the phones. The independent testing from three expert firms confirmed these findings, identifying the manufacturing flaws with the batteries themselves.

Was the design of the Note 7 at fault?

In short, no. While the faults were squarely within the manufacturing and design of the batteries, the Note 7 design didn’t directly impact upon the failures, though Samsung’s specifications for the batteries might have indirectly led to the failures. In short, Samsung demanded a high capacity battery which had to fit into an exacting, tight space. Not ordinarily a problem, but combined manufacturing defects and no space (literally) for failure meant the Note 7 line faced a likely outcome – battery failure.

What have they learned?

Samsung has created a Battery Advisory Group comprising four experts from industry and academia, as well as instituting an 8-point safety check across all its future devices, mobile and otherwise. The company has also introduced specific teams working on each product line, and each core component, to ensure that safety is and remains the company’s highest priority.

The recall in Australia has gone extremely well, with over 95% of Note 7’s recovered. It’s anticipated that some have been retained as souvenirs, and others may have been taken overseas and dealt with in overseas recall programs, but the majority of Note 7 customers opted for a replacement Samsung product from the S7 line (around 75%), with few opting for a refund and switching to another brand.

Samsung is confident that it can rebuild consumer trust, and the results of this investigation support that view — they’ve left literally no stone unturned in finding the root cause of issues, and we’re left assured, with some confidence, that we won’t see a repeat of this situation with Samsung devices in future.

Better yet, Samsung is sharing its learnings with industry standards bodies in a hope that other manufacturers of battery technology can learn from what happened here, and avoid it happening again in future.